DX coding (short for Digital IndeX) for 35mm film cartridges was originally introduced by Kodak in 1983 and, in contrast to some other systems, was able to establish itself on the market very quickly. Many camera and film manufacturers quickly adapted to the new information system, and its spread increased very fast. The DX code became the industry standard and, with a few exceptions, every 35mm film still has a DX code today, it simplifies the handling of 35mm film and includes the following components:

- a checkerboard code on the cartridge

- a bar and number code on the cartridge

- an information field on the cartridge

- a barcode on the negative film itself

What information does the DX code contain?

The checkerboard code

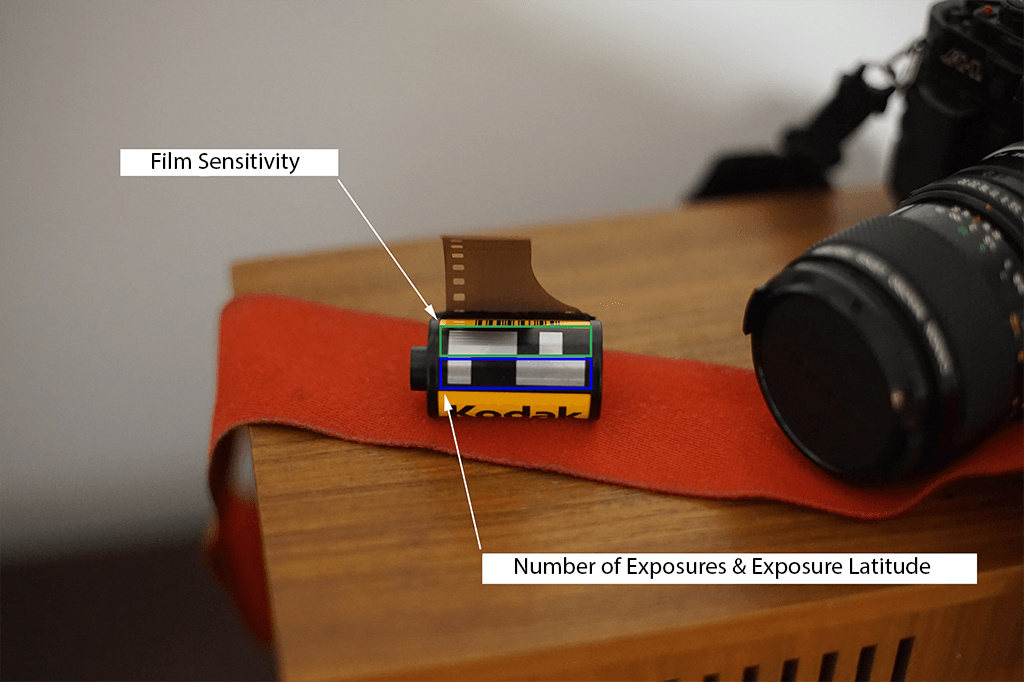

The checkerboard code contains information about the exposure, i.e. film sensitivity, the number of possible exposures, and the exposure latitude. Most newer automatic cameras read all this information from the cartridge and then take it into account when exposing the image. However, older or simpler models only take film speed into account.

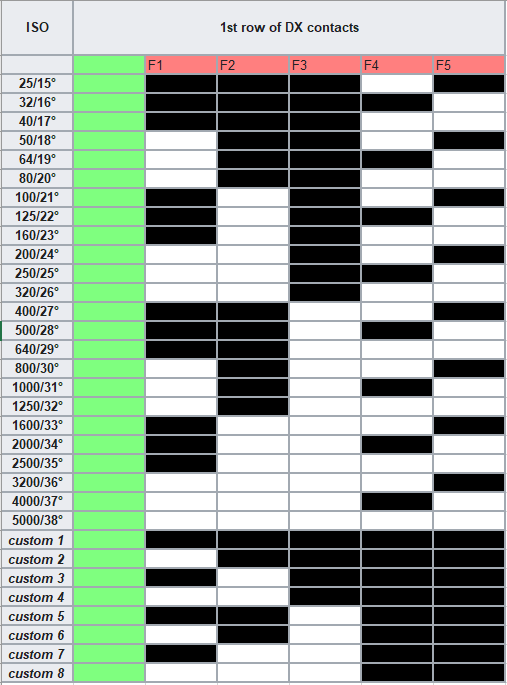

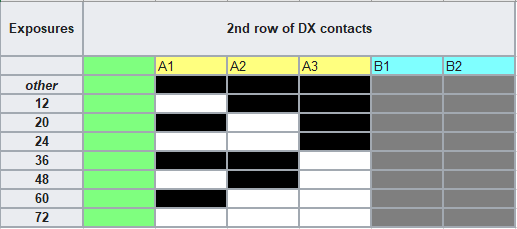

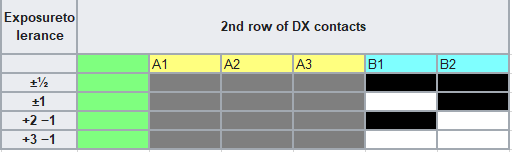

The top row of the checkerboard pattern describes film speed, while the bottom row describes the number of exposures and exposure latitude.

The tables below visualize all possible DX code options. (F = film speed, A = number of shots, B = exposure latitude)

The Barcode

The barcode helps printshops to process films automatically, it contains information on the country of manufacture, manufacturer, film type, sensitivity, film length, and the recommended processing method. If the film also has a barcode on the edge of the film, the product ID is entered here, and it is also only relevant for automatic film processing.